Today we will talk about the necessary steps to keep in mind before and during the start-up of a new barrier product/recipe:

- Most of the times the entire system is purged with Polyethylene during the shutdown or changeover to a new recipe specially all those layers with Barrier resin, Tie resin, Colors, or any heat sensitive resins with masterbatches etc.

- Check the inventory of the all the resins required for the production including the resin grade on the bag/box etc. If using a leftover material than please make sure you have the right material and is free from any contamination.

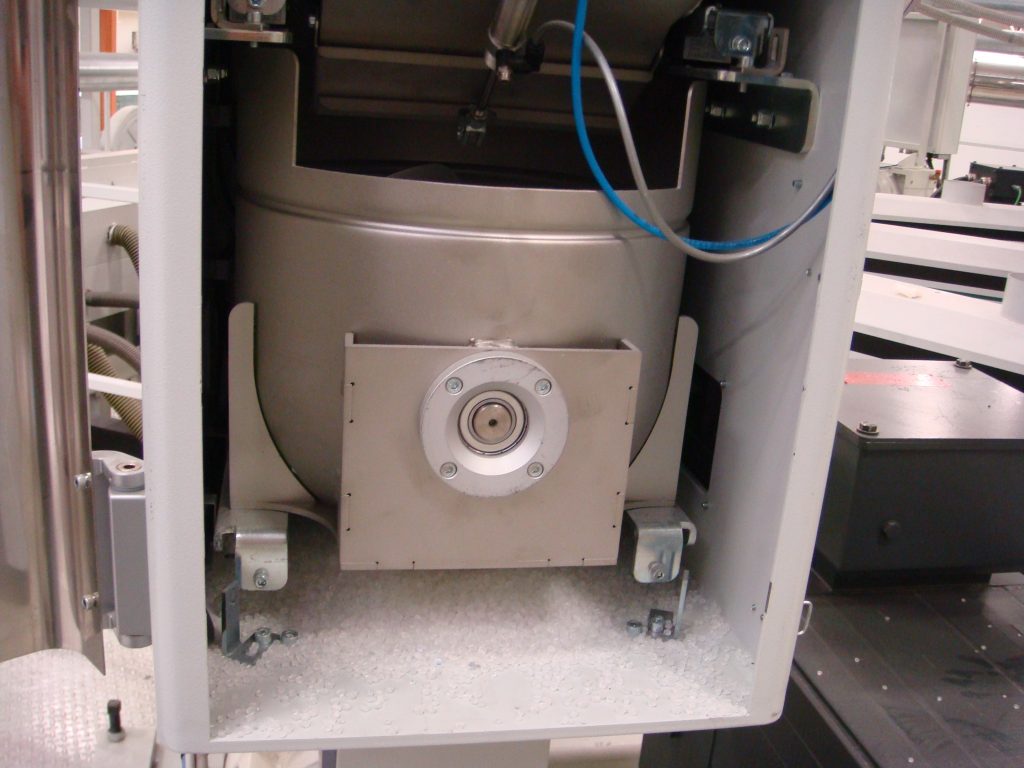

- Clean all the hoppers and mixers and make sure there are no any residual particles of previously used barrier resin like PA or EVOH etc., no color, additives or any other foreign particles in the hoppers, mixers or in the connected hoses.

- Verify that you have entered the right temperatures for the particular layer starting from feed section to the die.

- If it’s a new recipe trying for the first time than it is advisable to change the resins one at a time except the ones with PE. The layers with PE can be changed all at the same time.

- Prioritize the resin changeover sequence and start with the cheaper material first and barrier materials like PA and EVOH at the last.

- Check all the layer ratios prior to switching into “AUTO” mode.

- If draining the hoppers: Make sure there is no mix-up of resins. Label all the bags/boxes properly.