Troubleshooting & Maintenance Services

Extru-tech Solutions has experience and expertise in the Design, Manufacturing, and Assembly of Plastic Extrusion machinery and that is why we can help you in troubleshooting the process and Maintenance of your expensive machinery.

Process Improvment

Having quality issues, high rate of scrap, low output, gels, instability or any other problem related to the process we will find the solution in the most efficient manner.

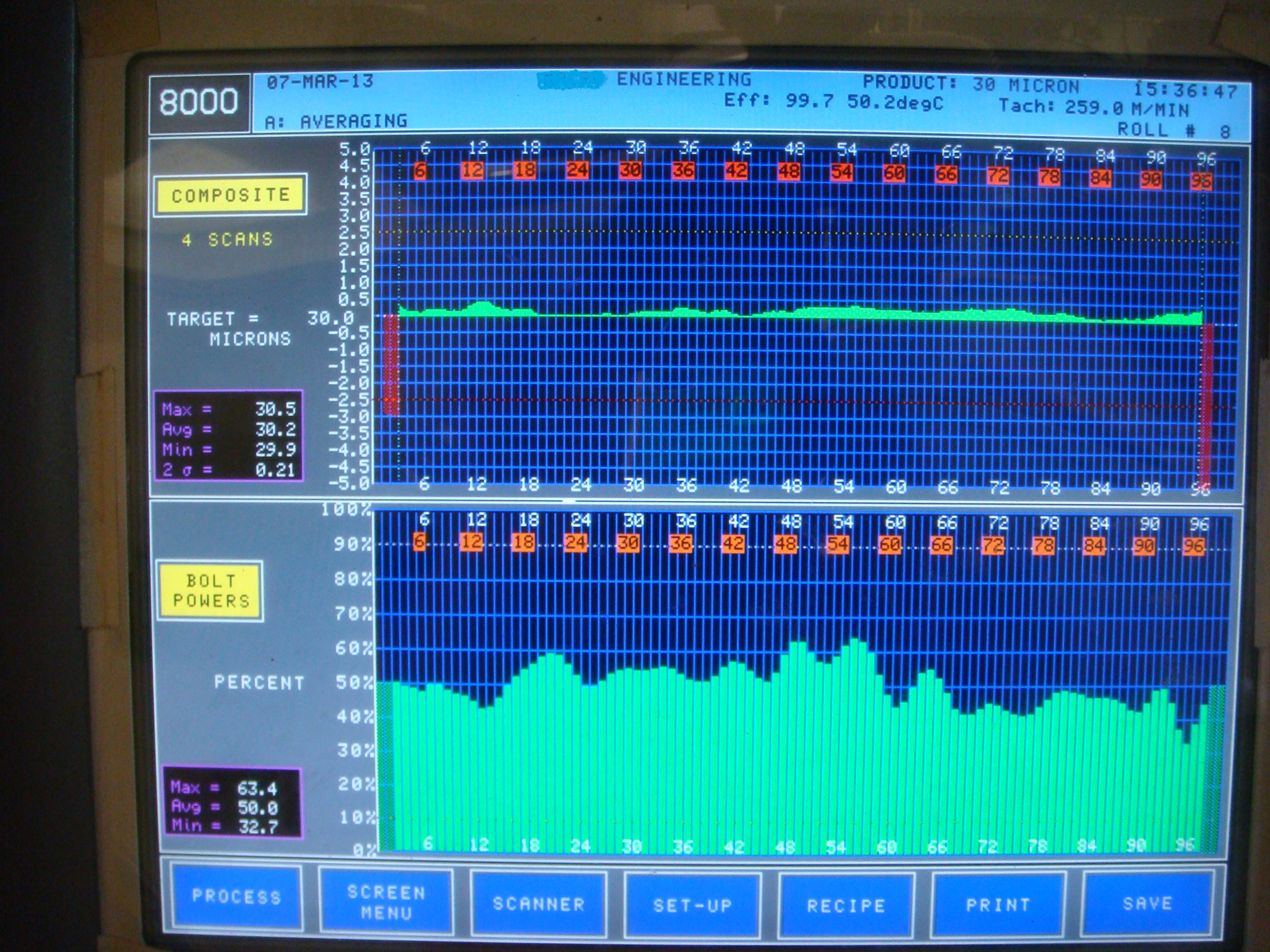

You may not know but the thickness variation problem hits you financially in consuming more resin as well as more rejections. According to simple calculation, improving the thickness variation just by 2.5% can save you over $70,000 per year.

Let us explain, and start saving!!!

Troubleshooting

Thickness variation, width variation, gauge bands, excessive noise from the extruder, die gap adjustment, air ring related problem, winding issues, telescopic rolls, tension issues or any other issues related to the machine, we can troubleshoot all these problems with our expertise and experience. We can help you in minimizing scrap percentage, increasing output and minimizing or eliminating the number of complaints.

Continuous Improvement & Evaluation Services

Extru-tech exclusive service helps you in continuously improving your products. Sometimes it is difficult for the full time employees to pay attention on the problem areas, because of many reasons for example: the new employees will think that “this is the way it should be”, the experienced employees might not be aware of the problem or they don’t have enough time to think about those improvement areas. This is when the services of an outside company become essential because they will see the things in different perspective.

The idea of continuous improvement is not to change the things up-side down rather the approach should be slow and steady and last but not the least the approach should be employee friendly. The employees have to understand the reason for any changes imposed on them and also the proposed changes have to be realistic.

Preventive Maintenance

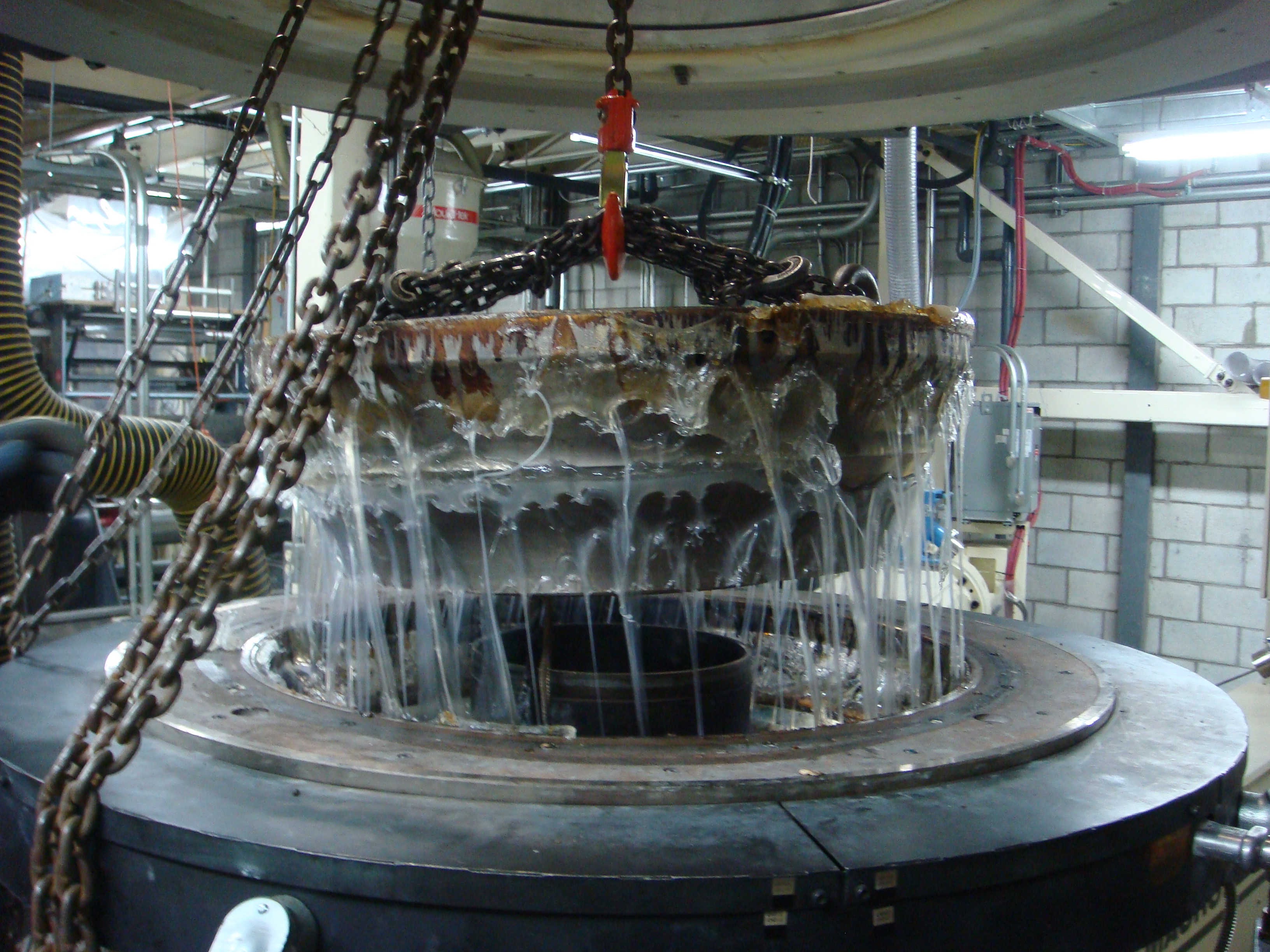

It is not necessary that a good quality machine will always give you good quality product. Over a period of time the parts will wear out and require maintenance and or replacement. The best option for a better quality product is to do the preventive maintenance of any machinery. But in real life it is difficult to follow the routine especially with the lack of manpower and the production commitments. In this situation the best option is to retain the services of an experienced and professional company who will schedule and provide this service on routine basis. This can save lots of money to the production company in the form of less scrap, less rejections and unexpected break downs.

Break Down Maintenance

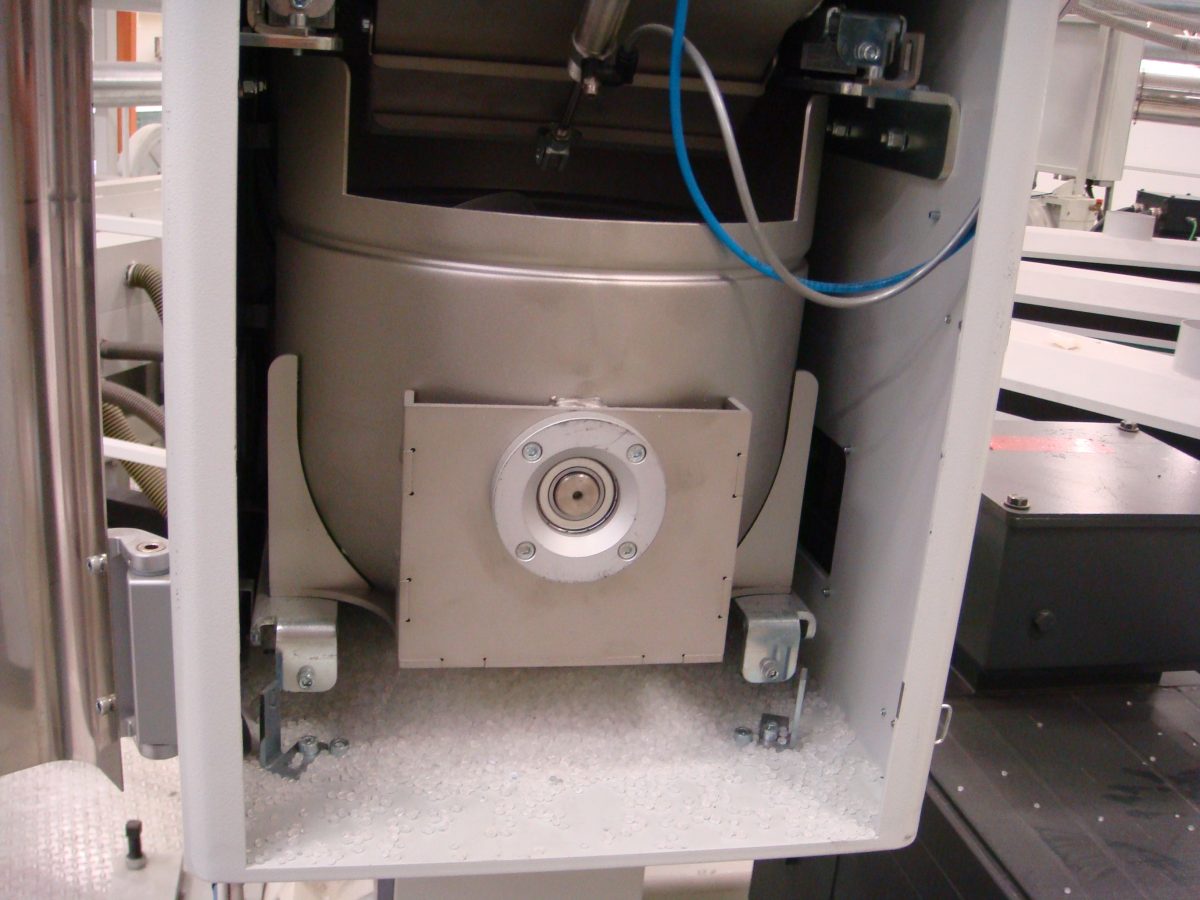

If the line is in break down due to any problem or if it is a scheduled maintenance we offer our services for the cleaning and evaluation of the key components requiring expertise and knowledge.

Extru-tech Services will service/clean the extruders, dosing system, adaptors and die. At the same time we will evaluate the performance and life of the screws and dies. We also check the heaters and thermocouples for proper functioning. Cleaning these parts on regular basis can have huge impact on the machine performance as well as on the quality of products.

Training Services

Extru-tech Solutions provide technical training to the people involved in Plastics Extrusion. The trainings can be arranged for the Process people, Operators and Supervisors as per their understanding of the Extrusion knowledge level.